cotton picking machine mechanism

It has a super long time continuous working capacity. The mechanical cotton picker is a machine that automates cotton harvesting in a way that reduces harvest time and maximizes efficiency by eliminating had picking.

A large plow-type attachment is shown attached to the undercarriage.

. High and new technologies are widely used in the self. There are two types of pickers in use today. The rear half of the engine is also visible.

This stripper saves cost involved in manual labour and eliminates drudgery for women and children. Ii Devices to remove the cotton from open bolls. One of the main operations in a factory for sewing cloth products is to pick up cloth parts provide them to a sewing machine and sew them together.

Handheld Cotton Picking Machine. Rembert and Jedidiah Prescott patented a cotton. The current cotton picker is a self-propelled machine that removes cotton lint and seed seed-cotton from the plant at up to six rows at a time.

In 1850 Taylure and Paige made the first attempt to develop a mechanical cotton picker with the intent on replacing manual labor. Others tried static electricity. It has a lasting service life.

No longer would farmers have to rely on laborers to go out and work the fields all day picking cotton off the bollsinstead they could invest in a cotton picker that. Also in 1850 Samuel S. Others tried to adapt grain threshing machines to cotton.

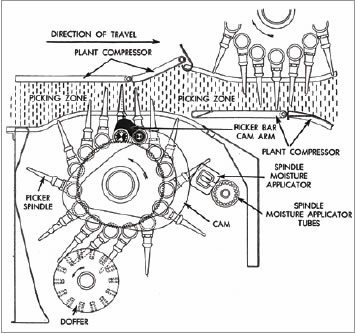

Cotton harvester harvester cotton picking machine. I An arrangement for guiding the plants into the picking zone and providing necessary support while the seed cotton is being removed. A cotton picking machine comprises a chassis for moving the machine in a traveling direction a vacuum pump provided to create a predetermined vacuum and a cotton picking unit including a.

Weft is withdrawn from the package through a tension device weft tensioner shuttle feeder scissor and weft end gripper. The machine is available in two models. Using the Cotton picking machine the speed is increased from 50 to 200 as compared to manual picking efficiency.

Introduction of Cotton Picking Machine. The picker or spindle idea drew the most attention. A spindle was a rod or prong that could poke into a cotton boll and rotate to spool up the fibers easily pulling away the boll.

After decades of work to perfect the harvester other manufacturers soon marketed one-row and two-row machines either as tractor-mounted or self-propelled units10 DIFFUSION. They are also found in Arkansas. In this paper we introduce a novel robotic end-effector for pick-and-release of a sheet of cotton cloth.

The performance for the machine is stable and reliable. The cotton picking machine dramatically increases the cotton - picking efficiency. Classification Of Picking Mechanism Loom Weaving Loom Shuttle Loom Cotton picking machine is designed for cotton picking it can fulfill the cotton-picking operation in 6610cm or 688cm width of cotton planting mode.

The team went to Mansukhbhai Patel who has made the cotton stripper machine. Then a doffer which acted like a large comb would strip the cotton from the spindle. Following are the basic components of a mechanical picker.

It has a super long time continuous working capacity. Cropped copy-photograph of a Farmall cotton-harvesting machine. The automatic cotton picking machine available here are driven by gears and the rotary blades are sharp and productive ensuring higher yields.

Early on some mechanical engineers tried to pick the cotton with pneumatic mechanisms that acted like giant vacuum cleaners. It is equipped with a bigger hopper which can extend the picking time greatly and boast large capacity in the field. Tion of spindle picking machines that simulated hand harvesting by rotating moistened barbed spindles through the cotton plant and pulling the bolls from their bur.

India the worlds largest producer of cotton contains more than 4 million cotton farms that are less than 5 acres. The cotton picking machine dramatically increases the cotton - picking efficiency. See how a modern John Deere cotton picker harvests cotton through 4k video using drones and GoPros Subscribe to our channel and see our other farm videos.

Each work starts with a lot of cloth. Others tried mechanical fingers or prongs to remove the cotton lint fibers to be spun into cloth. It is available with suction feed as auxiliary attachment.

It has a lasting service life. Easily pickingsave the labour cost. Finally a flow of air would suck the cotton off the doffer.

The development of the mechanical cotton picker goes back to the early 1930s and its proliferation and improvement in the decades that followed made for significantly easier harvesting of cotton. It improves the quality of cotton. The word Farmall is seen on the console immediately in front of the steering wheel.

The picker or spindle type machine was designed to pick the open cotton from the bolls using spindles fingers or prongs without injuring the plants foliage and unopened bolls. One is the stripper picker primarily found in use in Texas. These farms are incapable of large-scale mechanization due to small farm size and irregular farm shape.

Recently pneumatic cotton picker can be used as a mechanism which would reduce the harvest cost and maintain the cotton fiber quality comparing with the. It processes 400 kg cotton per hour. The performance for the machine is stable and reliable.

You can also get your hands on powerful combined cotton picking machine for wheat rice and soybean harvests. The cotton picking machine dramatically increases the cotton - picking efficiency. Working Principle of Projectile Weaving Machine.

Features - Cotton Picking. With a team of peers we first developed a handheld roller-based picking device that demonstrated increased. Cotton picking machine is designed for cotton picking it can fulfill the cotton-picking operation in 6610cm or 688cm width of cotton planting mode.

At the receiving side the weft end gripper is positioned to grip the weft after reception. Using the Cotton picking machine the speed is increased from 50 to 200 as compared to manual picking efficiency. The picking arm has released the projectile which is shown in the guide teeth at the mid-shed position.

Fabric products are assembled by performing this work in various processes.

How Do We Pick Cotton Version 2 Baler Pickers Youtube

Selection Of Cotton Harvesting Mechanism Results And Discussion Circular Economy For The Management Of Operations

Warp Stop Weaving Machine Loom Loom Weaving

Picking Mechanism On Projectile Weaving Machine Weaving Machine Weaving Industrial Fabric

Cotton Harvesting Wessels Living History Farm

5 Wheel Take Up Mechanism 5th Wheels Weaving Machine Weaving

Beating Mechanism With Sley Loom Weaving Weaving Loom

Fm E 2 Lesson 18 Cotton Pickers Construction And Working Principles

Cotton Picking Machine The Portal To Texas History

International Harvester Cotton Harvesters Octane Press

Cotton Harvester Machine Britannica

How Do Cotton Harvesting Machines Work

Jacquard Shedding Mechanism Card Pattern Card Patterns Kinds Of Fabric

The Determination Of Variety Effect Of A Simple Cotton Picking Machine On Design Parameters Scialert Responsive Version

Beat Up Mechanism In Weaving Weaving Shuttle Loom Motion

Schematic Diagram 7 Wheel Take Up Mechanism Cotton Weaving Weaving Weaving Process

Maximizing Harvester Capacity Productivity

Eli Whitney Cotton Gin Patent Drawing By Dan Sproul Patent Drawing Eli Whitney Patent Prints

Positive Tappet Shedding Mechanism Positive And Negative Positivity Negativity